CENTRIFUGE EGG BREAKER MACHINE OVOTECH UDTJ-150

| CATEGORY: | INDUSTRIAL EGG MACHINES |

|---|

AUTOMATIC CENTRIFUGE EGG BREAKER MACHINE OVOTECH UDTJ-150

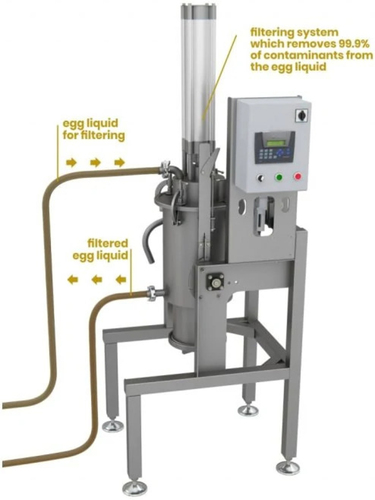

The UDTJ-150 egg centrifuge is an automatic machine. After filling the hopper with eggs, the eggs are cracked and the eggshells are filtered out with the use of a special rotating filter with a mesh size of 0.8 mm. Clean egg liquid is then transported to a placed container, and eggshells are automatically removed from the machine. The machine consists of a housing, the drive unit, hopper, tank, snail conveyor and sieve. The shells are ejected from the machine automatically with the help of a shell extraction mechanism through additional outlet mounted to the hopper. The machine should be cleaned every day after work, first unplugging the hopper by removing the sieve, shell extraction mechanism and removing the upper tank. Dismantled parts can be washed under running water, while the lower part containing the drive unit, can be wiped with a damp sponge. This part of the machine is usually not contaminated.

Dedicated for one-shift work cycle (8 hours). Max 900 000 eggs/month. Uses ball bearings. Reduces the volume of shells by 80%. Retrieves 98% of egg mass remaining in the broken shells. Centrifuge is electronically balanced. Washing the machine with the use of pressure washer is prohibited. A minimal amount (approximately 0.1%) of tiny eggshell particles no greater than 0.75 mm may be present in the obtained liquid egg. In order to mitigate this, we recommend leaving the liquid egg aside for 15-30 minutes before using it so that the particles will settle to the bottom of a bucket. All parts of our machines which come in contact with eggs are made out of stainless steel EN 1.4301 (AISI 304).

| CAPACITY | 20000 eggs/hour |

| POWER SUPPLY | 1.1 kW 400 V 3/N/PE 50/60 Hz |

| DIMENSIONS | 605x684x907 mm |

| MINIMAL WORKSPACE | 1500×1500 mm |

| WEIGHT | 80 kg |